Description

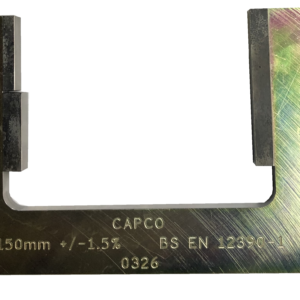

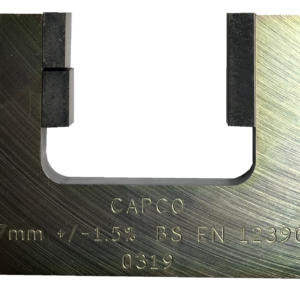

At CAPCO, precision and reliability are at the heart of every product we offer, and our Go No Go Gauge (100.0 – 15mm) is no exception. Designed to ensure accurate and consistent dimensional inspection, the Go No Go Gauge is an essential quality control tool for industries that demand tight tolerances—such as aerospace, automotive, and manufacturing. With over four decades of experience in supplying high-performance testing and construction equipment, CAPCO is proud to deliver tools engineered for excellence.

What is a Go No Go Gauge?

A Go No Go Gauge is a type of inspection tool used to check a workpiece against its allowed tolerance limits. It’s typically a two-ended gauge with one end (the “Go” end) that must fit into the part being measured, and the other end (the “No Go” end) that must not fit. If the part passes the “Go” and fails the “No Go,” it confirms that the component is within specification—ensuring both quality and compliance.

Learn more about the fundamental concept of Go/No-Go gauges in this Wikipedia article on limit gauges, which outlines their design and historical development.

Key Features of the 100.0 – 15mm Go No Go Gauge

Our Go No Go Gauge at CAPCO is engineered with strict compliance to British and international standards, offering the following benefits:

-

Precision Engineering: Manufactured to exact specifications, ensuring a consistent and reliable inspection every time.

-

Hardened Steel Construction: Built from high-grade hardened steel, ensuring long-lasting durability and resistance to wear.

-

Easy Identification: Each gauge is clearly marked for Go and No Go sides, allowing for rapid visual identification on the shop floor.

-

Wide Application Range: Ideal for checking diameters, bores, grooves, and external dimensions from 100.0mm down to 15mm.

-

Traceable Calibration: Supplied with full calibration certificates traceable to national standards, supporting ISO quality systems.

Go No Go Gauge – Precisely Measure with Capco’s Gauge

Used to check the internal size of Concrete Cube Moulds when calibrating to the above standards. Using these gauges is considerably quicker than using a vernier-caliper or internal micrometers.

Manufactured from gauge steel with hardened & ground end faces, the sizes and serial numbers are clearly marked.

Comes Complete with Capco Certificate.

UKAS calibration is available using code: GAUGE100ENUKAS

The CAPCO Advantage

As a trusted supplier since 1985, CAPCO has built a reputation for expertise, reliability, and customer-first service. Here’s why customers choose us:

-

Experienced Team: Our technical staff brings in-depth knowledge and real-world experience in industrial metrology and testing.

-

Comprehensive Support: We offer full technical support and after-sales service for all our measurement tools.

-

UK-Based Stock & Shipping: Fast, efficient delivery directly from our UK warehouse.

-

Custom Solutions Available: Need a gauge for a special application? Contact us to discuss bespoke manufacturing.

Looking for other essential testing equipment? Explore our range of materials testing products designed to support lab accuracy and industrial performance.

Investing in a high-quality Go No Go Gauge means investing in consistent quality, efficiency, and peace of mind. Trust CAPCO to deliver precision-engineered gauging tools that stand up to the demands of modern industry. Place your order today and experience the CAPCO standard.