Description

At CAPCO, we understand the importance of precise and reliable testing equipment in the construction and civil engineering industry. That’s why we proudly offer the Cube Mould Tamping Bar, a robust tool designed to assist in the proper compaction of concrete samples in cube moulds. Used by professionals in laboratories and on-site, this tamping bar plays a crucial role in achieving consistent, high-quality concrete test specimens that meet international standards.

What is a Cube Mould Tamping Bar?

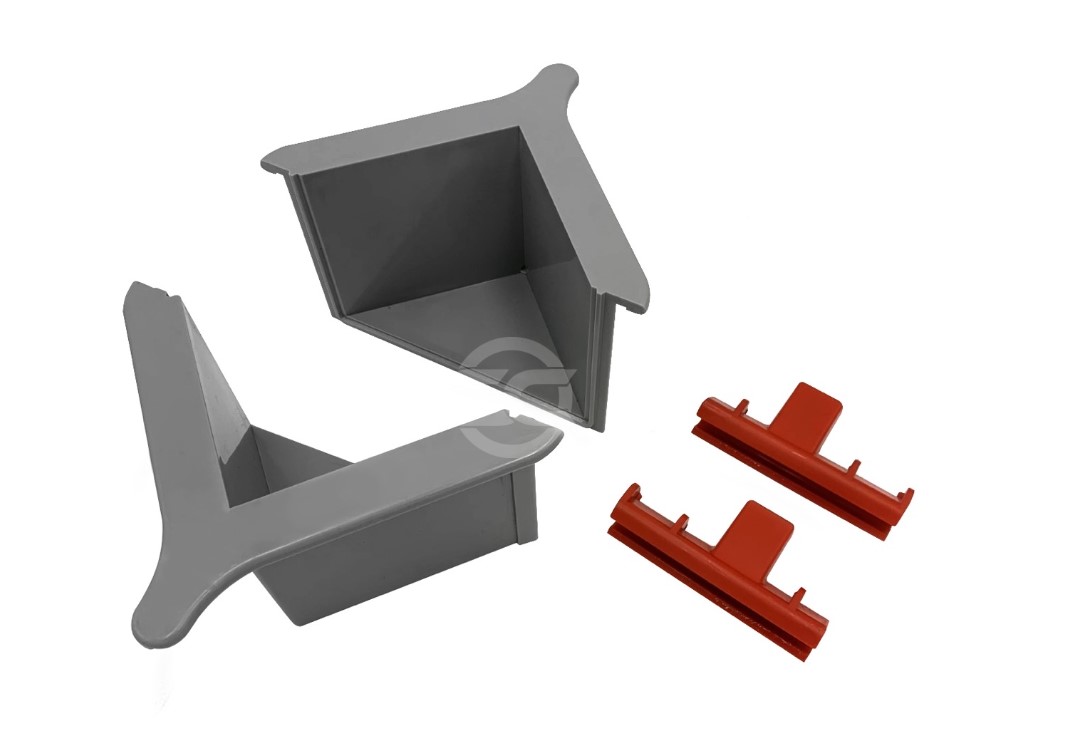

A cube mould tamping bar is a specialized instrument used for compacting concrete inside cube moulds during compressive strength testing. Ensuring uniformity and eliminating voids within the sample is essential for accurate test results. Typically constructed from durable materials such as stainless steel or hardened plastic, these tamping bars are built to withstand repeated use in demanding testing environments.

At CAPCO, our tamping bars are precision-engineered to deliver optimal performance and longevity. Our 100mm 2-Part Plastic Mould is designed to pair perfectly with our tamping bars, ensuring smooth operation and precise testing every time. If you’re working in quality assurance, material testing, or civil construction, this tool is a vital addition to your equipment arsenal.

Features and Benefits

The mould tamping bar offered by CAPCO meets all required industry specifications and is compliant with British and international testing standards. Key features include:

-

Durability: Manufactured from heavy-duty plastic or metal, it can withstand harsh conditions and repeated tamping.

-

Precision: Designed for consistent results, helping to eliminate air pockets and achieve uniform compaction.

-

Ease of Use: Ergonomically shaped for comfortable handling, making the testing process smoother and more efficient.

-

Compatibility: Works seamlessly with all standard 100mm cube moulds, including CAPCO’s own 2-part plastic mould.

Whether in a laboratory or on a construction site, using the right mould tamping bar can significantly improve the reliability of your test results. As improper compaction may lead to inaccurate readings and weak structures, investing in the right tool ensures you uphold safety, quality, and compliance in your construction projects.

Why Compaction Matters in Concrete Testing

Compaction of fresh concrete is critical to remove entrapped air and ensure that the concrete fully occupies the mould. Without proper tamping, voids may form, leading to misleading strength measurements and potentially unsafe construction decisions.

The tamping bar is integral to this process. According to Wikipedia’s page on concrete testing, improper compaction during cube testing can result in strength values significantly lower than the actual concrete mix potential. This is why standards like BS EN 12390-2 mandate strict procedures for making and curing specimens. The tamping bar ensures these standards are met, providing peace of mind and regulatory compliance.

The Choice of Industry Experts

At CAPCO, we’ve been supplying high-quality testing equipment to the construction and geotechnical sectors for years. Our commitment to precision, durability, and customer satisfaction makes us a trusted partner for companies across the UK and beyond. Our cube mould tamping bar is just one example of our extensive product range, tailored to meet the exacting needs of your industry.

Whether you’re performing tests in a controlled lab or on an active job site, you can rely on our tools to deliver dependable results. And if you’re looking for complementary products, don’t forget to explore our extensive range of concrete test moulds and accessories.

Applications and Usage Guidelines

To use the cube mould tamping bar correctly:

-

Fill the mould in layers – Typically, the mould is filled in two to three layers.

-

Tamp each layer – Apply a consistent number of strokes (usually 25) per layer with the tamping bar.

-

Even distribution – Ensure the strokes are evenly distributed across the surface.

-

Clean between uses – To maintain accurate results and extend the bar’s lifespan.

Regular calibration and inspection of your testing tools are crucial. According to ASTM’s guidelines for testing concrete, the reliability of test specimens is directly tied to the condition and quality of the equipment used.

The plastic moulds are a cheaper alternative to the cast iron mould and are made of robust plastic, resistant to abrasion, lightweight and very practical for field use.

Supplied in a Pack of 6.

*Test show they do not fully comply with the relevant standards*

Why Choose CAPCO?

As one of the UK’s leading providers of civil engineering testing equipment, CAPCO is proud to deliver products that meet the highest standards of quality and functionality. Here’s what sets us apart:

-

Expertise: With years of industry experience, we understand what professionals need on-site and in the lab.

-

Customer Service: Our team is here to provide expert advice and support every step of the way.

-

Reliable Inventory: We stock a comprehensive range of moulds, tamping bars, and testing apparatus to support your project from start to finish.

-

Fast UK Delivery: We ensure your equipment gets to you quickly and safely.

Our dedication to quality and service has made us a go-to supplier for laboratories, contractors, and educational institutions. Every product we offer—including our reliable cube mould tamping bar—is designed with performance and durability in mind.