Showing all 10 results

At Capco, we provide a specialist range of ball mills designed to meet the highest standards in sample preparation, research, and industrial production. Whether you’re working in materials science, pharmaceuticals, ceramics, or mining, our precision-engineered ball mills are built for performance, durability, and reliability. As one of the UK’s leading suppliers of laboratory equipment, we’re proud to offer innovative solutions backed by decades of experience and customer trust.

Ball Milling

Our selection includes laboratory-scale ball mills, bench-top models, and industrial-grade equipment suited for high-capacity grinding. Capco’s commitment to quality ensures that each product is built with precision, delivering consistently reproducible results. From small sample testing to high-volume grinding, our ball mills are an essential tool for ensuring accurate, homogeneous, and efficient particle size reduction.

Why Choose Capco Ball Mills?

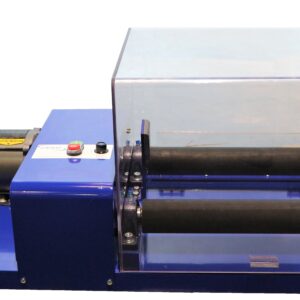

We understand that selecting the right equipment for your lab or production environment is critical. That’s why Capco’s ball mills are made using robust components, including heavy-duty steel drums, wear-resistant liners, and energy-efficient motors. Designed with ease of use in mind, our systems are simple to operate, maintain, and clean.

Whether you’re involved in mechanical alloying, mixing, blending, or size reduction, Capco ball mills offer optimal control and consistent performance. With features such as variable speed drives, digital timers, and safety interlocks, our machines are ideal for both precision research and commercial applications.

Customers from universities, government research facilities, and private industries continue to choose Capco for their milling needs because of our reputation for product quality and customer support.

Ball Milling: An Essential Technique in Sample Preparation

Ball milling is a widely used technique in material science and engineering for grinding and mixing materials down to a fine powder. The process involves placing materials into a rotating drum filled with grinding media—typically ceramic or steel balls—which impact and grind the material into smaller particles through friction and collision.

This method is incredibly effective for creating nanomaterials and enhancing the reactivity of powders in chemical processes. For researchers and technicians, ball milling allows precise control over particle size and distribution. It’s commonly used in the preparation of materials for X-ray diffraction, spectroscopy, and various mechanical tests.

At Capco, we understand the intricate demands of sample preparation. That’s why our ball milling equipment is engineered to deliver uniformity, repeatability, and efficiency. Our customers benefit from shorter preparation times, enhanced throughput, and excellent quality results across a wide range of materials.

Applications Across Multiple Sectors

Capco ball mills are used across many sectors, including:

-

Academic Research – for developing new materials and conducting lab-scale experiments.

-

Pharmaceuticals – for homogenizing active ingredients and excipients.

-

Mining and Metallurgy – for ore processing and mineral extraction.

-

Ceramics and Glass – for producing fine, uniform powders.

-

Environmental Science – for waste material analysis and preparation.

Our ball mills are built to adapt to diverse project needs. Whether you’re working with hard, brittle, fibrous, or soft materials, Capco has the equipment to help you achieve the desired outcome.

Customisation and Support

What sets Capco apart is our commitment to customer success. We offer customizable features on our ball mills to meet the specific requirements of your lab or production line. From choice of jar materials to programmable controls and protective enclosures, we tailor our solutions to your goals.

Moreover, our team provides comprehensive support—from initial consultation and setup to ongoing maintenance and troubleshooting. We’re more than just a supplier; we’re your trusted partner in achieving precision and productivity.

Looking for additional equipment to complement your ball milling setup? Check out our sample preparation equipment for a full range of tools designed to enhance your workflow.

Built on Trust, Backed by Expertise

Capco is a UK-based company with over six decades of experience in laboratory and industrial equipment. We are ISO certified and work closely with clients to ensure compliance with regulatory standards and industry benchmarks. Our reputation is built on engineering excellence, responsive service, and product reliability.

All our ball mills undergo rigorous quality checks and testing before delivery, ensuring peace of mind for every customer. Our products are designed to last, and our support team is always ready to assist with installation, operation, and maintenance queries.

The Science Behind Ball Mills

To better understand the mechanics and applications of a ball mill, it’s helpful to review the underlying scientific principles. A ball mill functions on the principle of impact and attrition. As the drum rotates, the grinding media cascade, creating shear forces that reduce the material into smaller, more uniform particles. This allows for precise control over material properties, surface area, and reactivity.

Ball mills are used in both dry and wet grinding processes. The ability to fine-tune operational parameters such as speed, grinding duration, and media type allows for exceptional versatility.

According to Wikipedia, ball mills have evolved significantly over the years, with modern versions offering much-improved energy efficiency, safety, and performance metrics. This makes them indispensable in contemporary laboratories and manufacturing environments.

Choose Capco for Your Ball Mill Requirements

If you’re looking for a ball mill that delivers consistent, high-quality results, Capco is your go-to solution. Our equipment is designed to meet the evolving demands of scientific and industrial communities, and we’re committed to helping our clients achieve exceptional outcomes with every project.

-

BALL MILL MODEL 11 ONE TIER VARIABLE SPEED

£0.00 -

BALL MILL MODEL 11 TWO TIER VARIABLE SPEED

£0.00 -

BALL MILL MODEL 12 VARIABLE SPEED

£0.00 -

BALL MILL MODEL 2 VARIABLE SPEED

£0.00 -

BALL MILL MODEL 3 VARIABLE SPEED

£0.00 -

BALL MILL MODEL 4 VARIABLE SPEED

£0.00 -

BALL MILL MODEL 6 VARIABLE SPEED

£0.00 -

BALL MILL MODEL 7 VARIABLE SPEED

£0.00 -

BALL MILL MODEL 8 VARIABLE SPEED

£0.00 -

BALL MILL MODEL 9 VARIABLE SPEED

£0.00