Showing all 8 results

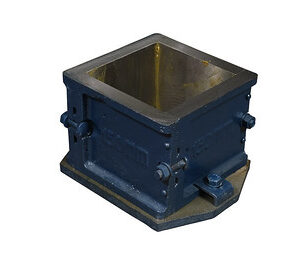

At CAPCO, we provide durable and high-precision 4-part cube moulds designed specifically for testing the compressive strength of concrete in construction and civil engineering applications. Manufactured to meet rigorous industry standards, our 4-part moulds offer engineers, technicians, and contractors a reliable solution for forming accurate concrete test specimens. Whether you’re working in a commercial lab or on-site, these moulds ensure consistent, repeatable results — a vital component of quality assurance in concrete production.

Our range of 4-part cube moulds includes various sizes and configurations, all constructed from high-grade materials to resist wear, corrosion, and deformation over time. These moulds are easy to assemble, clean, and reuse, offering long-term performance without compromising precision. With our deep industry knowledge and commitment to innovation, CAPCO stands out as a trusted supplier of construction testing equipment in the UK.

Why Use a 4-Part Cube Mould for Concrete Testing?

Concrete cube moulds are critical in verifying the compressive strength of concrete — a key performance metric that impacts the durability and safety of structures. The 4-part cube mould is preferred in many scenarios due to its simple yet secure assembly that allows for easy demoulding while maintaining specimen integrity.

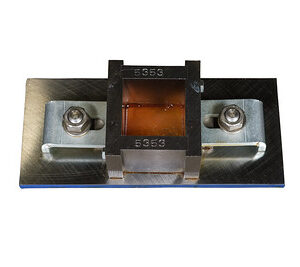

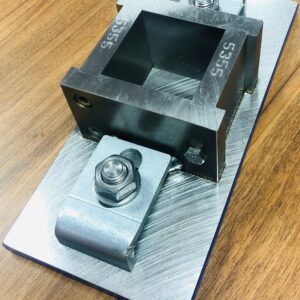

Each of the four parts is tightly clamped together to form a perfect cube, and the robust steel or cast iron construction ensures dimensional accuracy, even after repeated use. This precision is essential because even slight inconsistencies in cube dimensions can skew compressive strength results.

At CAPCO, all our cube moulds undergo strict quality checks to ensure they meet BS and EN standards. In addition, we offer moulds with features like a machined internal finish for smooth surfaces and easy cube removal. These benefits make our 4-part moulds ideal for laboratories, testing centers, and field applications alike.

Choosing the Right Cube Mould

Choosing the right cube mould depends on factors like cube size, test standards (BS, ASTM, or EN), and the concrete mix’s expected strength. At CAPCO, we guide customers through the selection process, ensuring the mould suits their unique testing needs.

We stock 100mm and 150mm cube moulds — the most commonly used sizes in the UK and Europe. Our team also offers expert advice on how to prepare, fill, and cure the concrete cubes properly to meet compliance and produce valid test results. Learn more about our full range of concrete testing equipment to support every stage of your project.

It’s important to use cube moulds that have clean, flat surfaces and are well-maintained, as worn-out moulds can lead to errors in readings. That’s why our 4-part moulds are designed for longevity and consistent performance, even after repeated demoulding and reassembly. When it comes to accuracy and compliance, CAPCO’s commitment to quality ensures that your results can be trusted.

Proper Handling and Maintenance

To get the most out of your moulds, it’s essential to follow best practices in cleaning, storage, and handling. Always clean the moulds immediately after use to prevent residual concrete from hardening inside. Use a mould release agent to facilitate easy demoulding and protect the surface finish. Store the moulds in a dry environment to prevent corrosion and deformation.

In addition to high-quality moulds, we offer tamper bars, vibrating tables, and curing tanks — everything required to carry out complete concrete strength testing according to international standards. For those new to the process, we recommend reviewing the Wikipedia page on concrete testing to understand the science behind cube tests and their importance in structural design.

Why CAPCO?

With over 30 years of experience in the materials testing industry, CAPCO is proud to be a leading supplier to construction professionals, government labs, universities, and private contractors across the UK and beyond. We blend industry expertise with engineering innovation to deliver tools that improve accuracy, productivity, and safety.

Our customer support team is always ready to assist with technical specifications, compliance standards, or product comparisons. Whether you’re ordering a single 4-part cube mould or outfitting an entire lab, our goal is to help you make informed decisions with confidence.

Applications Across Industries

The use of 4-part moulds extends beyond routine construction. They’re also vital in research labs, academic institutions, and large-scale infrastructure projects like highways, dams, and bridges. These sectors demand uncompromising precision and traceability — exactly what our cube moulds provide.

We work closely with clients to supply moulds that comply with both British and international testing standards, including BS 1881 and EN 12390. This ensures that every test carried out with CAPCO equipment aligns with regulatory requirements and industry benchmarks. Our moulds are a smart investment for professionals who value durability, reliability, and accuracy.

-

100mm 4 PART CUBE MOULD

£0.00 -

150mm 2 PART -LABORATORY CUBE MOULD

£0.00 -

150mm 4 PART CUBE MOULD

£0.00 -

40mm CUBE MOULD

£0.00 -

50mm CUBE MOULD

£0.00 -

70.7mm LABORATORY CUBE MOULD

£0.00 -

75mm LABORATORY CUBE MOULD

£0.00 -

Concrete Cube Mould

£0.00