Description

Plast Mould: Precision Engineering for Concrete and Construction Applications

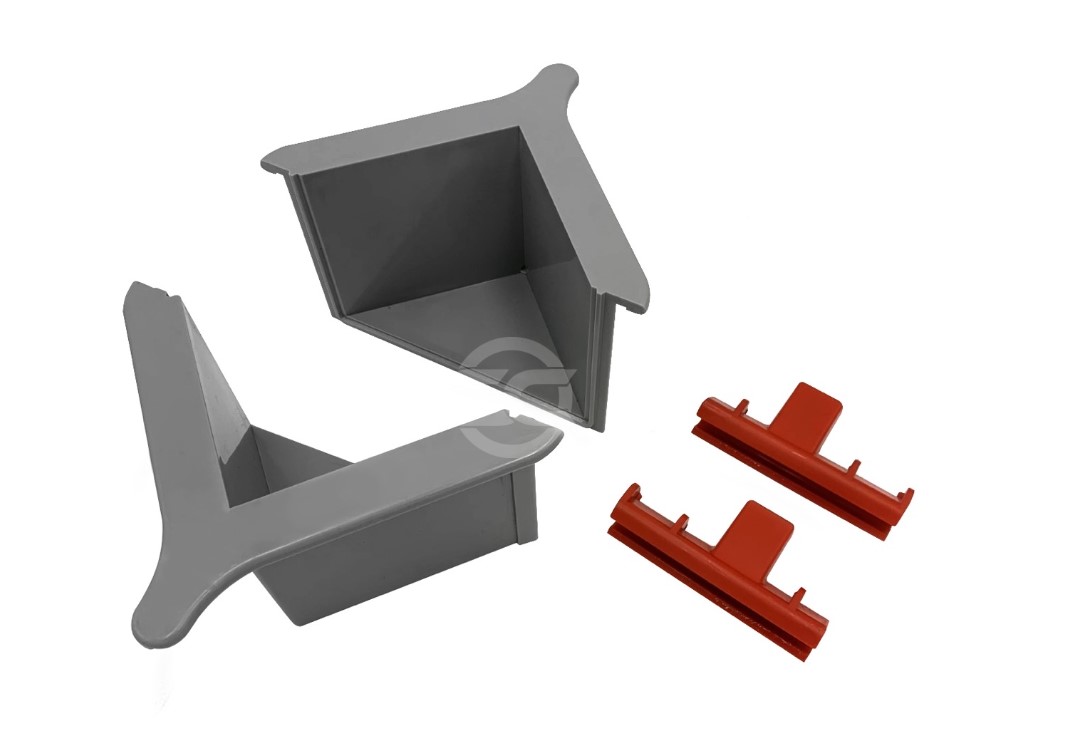

When it comes to crafting durable, uniform concrete cubes for construction testing, the 150mm 2-Part Plastic Cube Mould from Capco stands as a benchmark in quality and reliability. Designed for engineers, laboratories, and construction professionals, our plast mould combines robust materials, precision engineering, and user-friendly features to streamline your concrete compression testing processes. Built to meet BS EN 12390-2 standards, this mould ensures consistent results while reducing operational downtime. At Capco, we specialize in delivering innovative moulding solutions that prioritize longevity, accuracy, and ease of use—making us a trusted partner in the construction industry.

Key Features of the 150mm 2-Part Plastic Cube Mould

Capco’s plastic cube mould is engineered to address the rigorous demands of concrete testing. Key features include:

- High-Density Polypropylene (HDPP) Construction: Resistant to corrosion, impact, and extreme temperatures, ensuring long-term durability.

- Two-Part Design: Simplifies demolding and minimizes damage to cured concrete samples.

- Precision Calibration: Manufactured to ±0.2mm tolerances for compliance with international testing standards.

- Reusable and Low Maintenance: Non-stick surfaces reduce residue buildup, while seamless assembly cuts cleaning time.

Whether you’re testing concrete for bridges, highways, or high-rise buildings, this mould guarantees repeatable accuracy—a critical factor in structural integrity assessments.

The Science Behind Plast Moulding: How Capco Delivers Excellence

Plast moulding is a sophisticated manufacturing process that demands expertise in material science and precision tooling. At Capco, we utilize advanced injection moulding techniques to create moulds that withstand high-pressure environments and repetitive use. Our process involves:

- Material Selection: High-density polypropylene is chosen for its dimensional stability and resistance to chemical degradation.

- Tooling Design: CAD-driven prototypes ensure perfect alignment of the two-part mould, eliminating gaps or leaks.

- Quality Assurance: Each mould undergoes rigorous stress-testing to verify compliance with BS EN and ASTM standards.

This meticulous approach ensures that every 150mm cube mould we produce meets the exacting requirements of modern construction projects. For more insights into our manufacturing ethos, explore our range of construction testing equipment.

Applications Across Industries

Capco’s 150mm plastic cube mould is versatile, serving sectors such as:

- Civil Engineering: Testing compressive strength of concrete for infrastructure projects.

- Research Laboratories: Conducting material performance studies under controlled conditions.

- Construction Material Suppliers: Quality assurance for pre-mixed concrete batches.

External resources like Wikipedia’s guide to injection moulding and ScienceDirect’s polymer processing research provide deeper insights into the technology behind our products.

Why Choose Capco’s Plast Mould Solutions?

With over two decades of experience, Capco has cemented its reputation as a leader in mould manufacturing. Our commitment to EEAT (Expertise, Authoritativeness, Trustworthiness) is evident through:

- Industry Certifications: Compliance with ISO 9001 quality management systems.

- Customer-Centric Support: Technical assistance and rapid replacement parts delivery.

- Sustainability: Recyclable materials and energy-efficient production methods.

We don’t just sell moulds—we deliver solutions that enhance operational efficiency and data reliability.

The plastic moulds are a cheaper alternative to the cast iron mould and are made of robust plastic, resistant to abrasion, lightweight and very practical for field use.

Supplied in a Pack of 6.

*Test show they do not fully comply with the relevant standards*

Conclusion: Elevate Your Testing Standards with Capco

In an industry where precision is non-negotiable, the 150mm 2-Part Plastic Cube Mould exemplifies Capco’s dedication to innovation and quality. Whether you’re a seasoned engineer or a lab technician, our plast mould ensures your concrete samples meet global benchmarks. Explore our product range today and discover how Capco can empower your projects with cutting-edge testing tools.